Anthony Ragone

Prof. Joseph A. Betz, R.A.

ARC 253

1/27/2010

Bridge

Research

ARCH

BRIDGE

Arch

bridges are one of the oldest types of bridges and have great natural strength.

Instead of pushing straight down, the weight of an arch bridge is carried

outward along the curve of the arch to the supports at each end. These

supports, called the abutments, carry the load and keep the ends of the bridge

from spreading out. Arch bridges work by

transferring the weight of the bridge and its loads

partially into a horizontal thrust restrained by the abutments at either side.

A viaduct

(a long bridge) may be made from a series of arches, although other more

economical structures are typically used today.

Try It!

How

do the abutments support an arch bridge?

![]() Cut

a strip of cardboard that's about one inch by 11 inches. Gently bend the strip

so that it has a curve. Position the cardboard on a table so that it resembles

an arch. Press down on the center of the arch. What happens to the ends of the

cardboard?

Cut

a strip of cardboard that's about one inch by 11 inches. Gently bend the strip

so that it has a curve. Position the cardboard on a table so that it resembles

an arch. Press down on the center of the arch. What happens to the ends of the

cardboard?

Next,

place a stack of books at each end of the arch. Press again. Now what happens?

Notice how the stacks of books act as abutments, keeping the ends of the arch

from spreading apart.

Next,

place a stack of books at each end of the arch. Press again. Now what happens?

Notice how the stacks of books act as abutments, keeping the ends of the arch

from spreading apart.

When supporting its own weight and the weight of crossing traffic, every part

of the arch is under compression. For this reason, arch bridges must be made of

materials that are strong under compression.

|

The Pont du Gard aqueduct |

The

Romans used stones. One of the most famous examples of their handiwork is the

Pont du Gard aqueduct near Nîmes, France. Built before the birth of Christ, the

bridge is held together by mortar only in its top tier; the stones in the rest

of the structure stay together by the sheer force of their own weight.

|

The

New River bridge |

Today

materials like steel and pre-stressed concrete have made it possible to build

longer and more elegant arches, including a spectacular 1700 foot span in New

River Gorge, West Virginia. (More typically, modern arch bridges span between

200-800 feet.)

|

Centering under construction |

Constructing an arch bridge can be tricky, since the

structure is completely unstable until the two spans meet in the middle. One

technique is to build elaborate scaffolding, or "centering," below

the spans to support them until they meet. A newer method supports the spans

using cables anchored to the

|

|

|

Arch

construction using cable supports |

ground

on either side of the bridge. In situations where there is an active water or

road way below, this method allows contractors to build without disrupting traffic.

|

The Natchez Trace bridge |

One of the most revolutionary arch

bridges in recent years is the Natchez Trace Bridge in Franklin, Tennessee,

which was opened to traffic in 1994. It's the first American arch bridge to be

constructed from segments of pre-cast concrete, a highly economical material.

Two graceful arches support the roadway above. Usually arch bridges employ

vertical supports called "spandrels" to distribute the weight of the

roadway to the arch below, but the Natchez Trace Bridge was designed without

spandrels to create a more open and aesthetically pleasing appearance. As a

result, most of the live load is resting on the crowns of the two

arches, which have been slightly flattened to better carry it. Already the

winner of many awards, the bridge is expected to influence bridge design for

years to come.

Beam

Bridges or Girder Bridge

Beam bridges are the simplest kind of bridge

today. They are a direct descendant of the log bridge,

now more commonly made from shallow steel 'I' beams,

box girders, reinforced concrete, or post-tensioned

concrete. It is

frequently used in pedestrian bridges and for highway overpasses and flyovers.

As is its ancestor, this bridge is in structural terms the simplest of the many

bridge types. Like most bridges that are

characterized by how they are supported, beam bridges consist of one horizontal

beam with 2 supports usually on either end.

|

Beam bridge |

A beam

or "girder" bridge is the simplest and most inexpensive kind of

bridge. According to Craig Finley of Finley/McNary Engineering, "they're

basically the vanillas of the bridge world."

In its most basic form, a beam bridge consists of a horizontal beam that is

supported at each end by piers. The weight of the beam pushes straight down on

the piers.

The beam itself must be strong so that it doesn't bend under its own weight and

the added weight of crossing traffic. When a load pushes down on the beam, the

beam's top edge is pushed together (compression) while the bottom edge is

stretched (tension).

Try It!

What happens when a load pushes down on a beam

bridge?

Take a flat eraser or a small sponge and slice a shallow notch across the top

and bottom. Create a beam bridge by supporting each end of the eraser (or

sponge) with a stack of books. Press down on the center of the bridge. What

happens to the top and bottom notches? Notice how the top notch squeezes

together in compression, while the bottom notch spreads apart under tension.

Pre-stressed concrete is an ideal material for beam

bridge construction; the concrete withstands the forces of compression well and

the steel rods imbedded within resist the forces of tension. Pre-stressed

concrete also tends to be one of the least expensive materials in construction.

But even the best materials can't compensate for the beam bridge's biggest

limitation: its length.

The farther apart its supports, the weaker a beam bridge gets. As a result,

beam bridges rarely span more than 250 feet. This doesn't mean beam bridges

aren't used to cross great distances—it only means that they must be

daisy-chained together, creating what's known in the bridge world as a

"continuous span."

|

Lake Ponchartrain Causeway, Louisiana |

In fact,

the world's longest bridge is a continuous span beam bridge. Almost 24 miles

long, the Lake Ponchartrain Causeway consists of two, two-lane sections that

run parallel to one another. The Southbound Lane, completed in 1956, is made up

of 2243 separate spans, while the Northbound Lane, completed in 1969, is pieced

together from 1500 longer spans. Seven cross-over lanes connect the two main

sections and function as pull-over bays in emergencies. Although impressive,

the Lake Ponchartrain Causeway bridge underscores the drawback of continuous

spans: they are not well suited for locations that require unobstructed

clearance below.

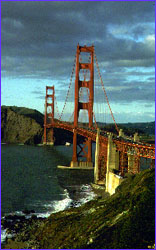

Suspension Bridge

Aesthetic,

light, and strong, suspension bridges can span distances from 2,000 to 7,000

feet—far longer than any other kind of bridge. They also tend to be the most

expensive to build. True to its name, a suspension bridge suspends the roadway from huge main

cables, which extend from one end of the bridge to the other. These cables rest

on top of high towers and are secured at each end by anchorages.

|

Suspension bridge |

|

Suspension

bridge anchorage |

The towers enable the main cables

to be draped over long distances. Most of the weight of the bridge is carried

by the cables to the anchorages, which are imbedded in either solid rock or

massive concrete blocks. Inside the anchorages, the cables are spread over a

large area to evenly distribute the load and to prevent the cables from

breaking free.

Try It!

What are the anchorages for?

![]() Tie two loops of string around

the tops of two hard cover books of similar size. Tie a third piece of string

to each loop so that it hangs loosely between the books. Press down on the

center string. What happens?

Tie two loops of string around

the tops of two hard cover books of similar size. Tie a third piece of string

to each loop so that it hangs loosely between the books. Press down on the

center string. What happens?

Next, stand two books about 10

inches apart. Put a stack of heavy books on one end of string to secure it to

the table. Then pass the string over each book (letting some string hang

loosely between the books). Place a second stack of books on the other end of

the string. Press again on the center of the string. What happens? Notice how

the anchorages (stacks of books) help to stabilize the bridge.

Next, stand two books about 10

inches apart. Put a stack of heavy books on one end of string to secure it to

the table. Then pass the string over each book (letting some string hang

loosely between the books). Place a second stack of books on the other end of

the string. Press again on the center of the string. What happens? Notice how

the anchorages (stacks of books) help to stabilize the bridge.

|

Akashi bridge cable

assembly |

Some

of the earliest suspension bridge cables were made from twisted grass. In the

early nineteenth century, suspension bridges used iron chains for cables.

Today, the cables are made of thousands of individual steel wires bound tightly

together. Steel, which is very strong under tension, is an ideal material for

cables; a single steel wire, only 0.1 inch thick, can support over half a ton

without breaking.

|

The

Humber bridge |

Currently,

the Humber bridge in England has world's longest center span—measuring 4,624

feet. But this record won't stand for long. In 1998, the Japanese will unveil

the $7.6 billion Akashi Kaikyo Bridge, linking the islands of Honshu and

Shikoku. The bridge's center section stretches a staggering 6,527 feet. To keep

the structure stable, engineers have added pendulum-like devices on the towers

to keep them from swaying and a stabilizing fin beneath the center deck to

resist typhoon-strength winds. Because suspension bridges are light and

flexible, wind is always a serious concern—as the residents of Tacoma,

Washington can surely attest.

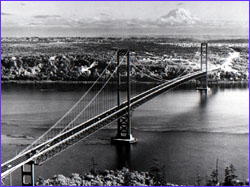

At the time it opened for traffic in 1940, the

Tacoma Narrows Bridge was the third longest suspension bridge in the world. It

was promptly nicknamed "Galloping Gertie," due to its behavior in

wind. Not only did the deck sway sideways, but vertical undulations also

appeared in quite moderate winds. Drivers of cars reported that vehicles ahead

of them would completely disappear and reappear from view several times as they

crossed the bridge. Attempts were made to stabilize the structure with cables

and hydraulic buffers, but they were unsuccessful. On November 7, 1940, only

four months after it opened, the Tacoma Narrows Bridge collapsed in a wind of

42 mph—even though the structure was designed to withstand winds of up to 120

mph.

|

New

Tacoma Narrows Bridge |

The

failure came as a severe shock to the engineering community. Why did a great

span, more than half a mile in length and weighing tens of thousands of tons,

spring to life in a relatively light wind? And how did slow, steady, and

comparatively harmless motions suddenly become transformed into a catastrophic

force? To answer these questions engineers began applying the science of

aerodynamics to bridge designs. Technical experts still disagree on the exact

cause of the bridge's destruction, but most agree the collapse had something to

do with a complex phenomenon called resonance: the same force that can cause a

soprano's voice to shatter a glass.

Today, wind tunnel testing of bridge designs is mandatory. As for the Tacoma

Narrows bridge, reconstruction began in 1949. The new bridge is wider, has deep

stiffening trusses under the roadway and even sports a slender gap down the

middle—all to dampen the effect of the wind.

Cable-Stayed Bridge

|

Cable-stayed bridge |

Cable-stayed

bridges may look similar to suspensions bridges—both have roadways that hang

from cables and both have towers. But the two bridges support the load of the

roadway in very different ways. The difference lies in how the cables are

connected to the towers. In suspension bridges, the cables ride freely across

the towers, transmitting the load to the anchorages at either end. In

cable-stayed bridges, the cables are attached to the towers, which alone bear

the load.

The cables can be attached to the roadway in a variety of ways. In a radial

pattern, cables extend from several points on the road to a single point at the

top of the tower. In a parallel pattern, cables are attached at different heights

along the tower, running parallel to one other.

|

Parallel

attachment pattern |

|

Radial

attachment pattern |

Try It!

How do

cable-stayeds work?

Stand up and hold your arms out horizontally at each side. Imagine that your

arms are a bridge, and your head is a tower in the middle. In this position,

your muscles are holding up your arms.

Try making cable-stayeds to support your arms. Take a piece of rope (about five

feet long), and have a partner tie each end of the rope to each of your elbows.

Then lay the middle of the rope on top of your head. The rope acts as a

cable-stayed and holds your elbows up.

Have your partner tie a second

piece of rope (about 6 feet long) to each wrist. Lay the second rope over your

head. You now have two cable-stayeds. Where do you feel a pushing force, or

compression? Notice how the cable-stayeds transfer the load of the bridge (your

arms) to the tower (your head).

Have your partner tie a second

piece of rope (about 6 feet long) to each wrist. Lay the second rope over your

head. You now have two cable-stayeds. Where do you feel a pushing force, or

compression? Notice how the cable-stayeds transfer the load of the bridge (your

arms) to the tower (your head).

Even though cable-stayed bridges look futuristic, the idea for them goes back a

long way. The first known sketch of a cable-stayed bridge appears in a book

called Machinae Novae published in 1595, but it wasn't until this

century that engineers began to use them. In post-World War II Europe, where

steel was scarce, the design was perfect for rebuilding bombed out bridges that

still had standing foundations. Cable stay bridges have begun to be erected in

the United States only recently, but the response has been passionate.

For medium length spans (those between 500 and 2,800 feet), cable-stayeds are

fast becoming the bridge of choice. Compared to suspension bridges,

cable-stayeds require less cable, can be constructed out of identical pre-cast

concrete sections, and are faster to build. The result is a cost-effective

bridge that is undeniably beautiful.

|

Sunshine Skyway bridge |

In 1988,

the Sunshine Skyway bridge in Tampa, Florida won the prestigious Presidential

Design Award from the National Endowment for the Arts. Painted yellow to

contrast with its marine surroundings, the Sunshine Skyway is one of the first

cable-stayed bridges to attach cables to the center of its roadway as opposed

to the outer edges, allowing commuters an unobstructed view of the magnificent

bay. Recently, in Boston, Massachusetts, a cable-stayed design was selected for

a new bridge across the Charles River—even though cheaper options were

proposed. City officials simply liked the way it looked.

Cantilever Bridge

A cantilever bridge is a bridge

built using cantilevers, structures that project

horizontally into space, supported on only one end. For small footbridges,

the cantilevers may be simple beams;

however, large cantilever bridges designed to handle road or rail traffic use trusses

built from structural steel, or box girders

built from prestressed concrete. The steel truss cantilever

bridge was a major engineering breakthrough when first put into practice, as it

can span distances of over 1,500 feet (460 m), and can be more easily

constructed at difficult crossings by virtue of using little or no falsework.